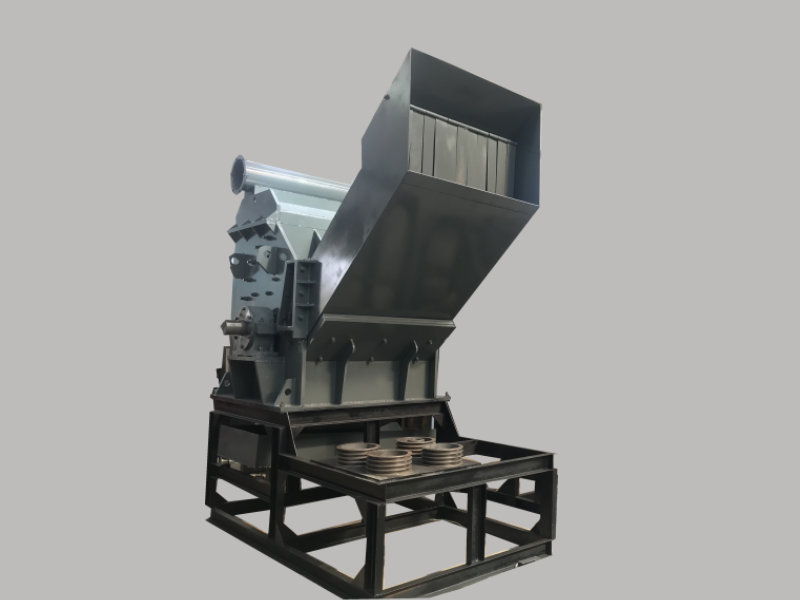

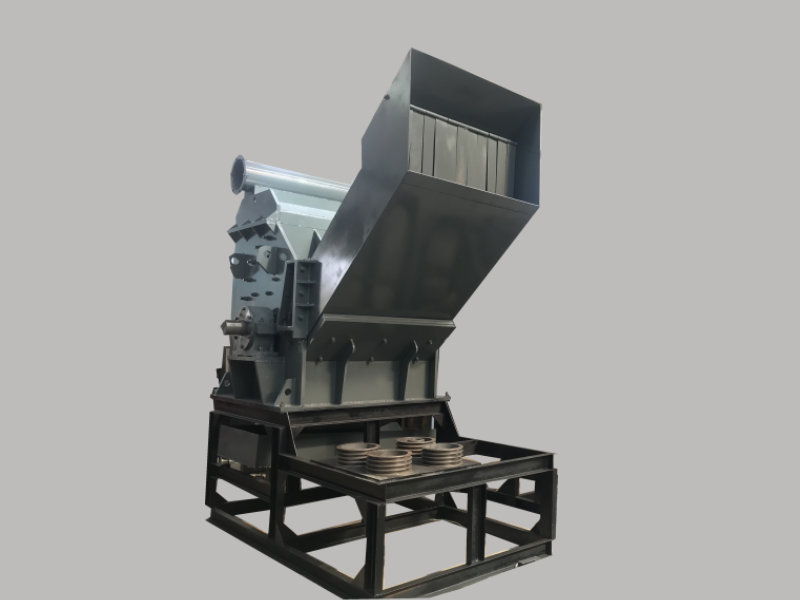

Name: Metal crusher

Model: DW1000

Motor :45kw

Capacity :1000T/H

Metal crusher is a environmental crusher for recycling the scrap metal wastes, like cans,metal wastes, we can crush them into small pieces, then we feed them into furnace to reuse themwe produced small-medium scrap metal crushing plant which are widely employed to crush and recycle pop cans, tin cans, metal food box, paint bucket, gas gasoline drum, oil filter, shell of refrigerator and washing machine, steel tile, light bar keel, etc.

Structure of scrap aluminum crusher : 1) The main shell is made of thick steel plate, lined with high manganese cast steel, can be replaced; 2) the host rotor has 11 steel plate installed in the horizontal axis, steel plate circumference distribution of six pin shaft, axial suspension of 10 hammer; 3)

Spindle with ball bearing support, circulating oil forced lubrication cooling, and equipped with temperature sensors; 4) The inlet is equipped with super-powerful binocular feeding device, the position of a high and one low, with the rotation, can loose bulk material gradually flattened into the machine. The machine uses a single motor and dual motor configuration of two, the user can choose according to the size of the transformer model configuration. Double-motor-configured paint barrel crusher effectively reduces the torque force, so that the paint bucket crusher energy saving, like broken shells, barrel metal objects can be used when a motor using machine inertia to break.

When working, you need to keep in mind and follow the operating precautions of the shredder to achieve safe production. The following are ten items that the editor has compiled that must be followed for your reference:

1. The shredder should be fixed on the cement foundation. If the working location is changed frequently, the metal shredder and motor should be installed on a base made of angle iron. If the crusher is powered by a diesel engine, the power of the two should be matched, that is, the power of the diesel engine is slightly greater than the power of the crusher, and the pulley grooves of the two should be consistent. The outer end faces of the pulleys should be on the same plane.

2. Before starting up, you must check whether the connecting bolts of each part of the metal shredder unit are tight, whether the tightness of the transmission belt is appropriate, and whether the power cord is in good condition. Whether the motor shaft is parallel.

3. Check whether the hammer head is in good condition, whether the aperture of the screen plate is appropriate, and whether there is any damage. Drag the belt by hand to check whether the spindle rotates flexibly and whether there is any jamming, collision or friction.

4. After turning on the machine, let the equipment idle for 2-3 minutes to check whether the rotor direction is correct and whether the sound is normal. It can only work after it rotates smoothly at rated speed.

5. Pay attention to the operation of the crusher at all times during work. The material should be fed evenly to prevent the feed port from being blocked. Do not overload the work for a long time. If any vibration, noise, excessive temperature of the bearings and body, or material spraying are found, stop the machine immediately for inspection and troubleshoot the problem before continuing to work.

6. When the machine is running, the operator is not allowed to leave the unit, nor is it allowed to disassemble the machine to observe the working conditions in the crushing room during operation. Maintenance tools are not allowed to be placed on the machine.

7. Operators should not wear gloves. When blockage occurs, it is strictly forbidden to put hands into the filler. When feeding materials, they should stand on the side of the crusher to prevent the face from being hurt by rebounding debris.

8. Do not stop the machine immediately after the work is completed. It should be idle for 2-3 minutes to allow all materials in the machine to be discharged. Cleaning and maintenance work should be carried out after shutdown.

10. After the crusher has worked for 300 hours, the bearings should be cleaned and the engine oil should be replaced. When shutting down for a long time, the belt should be removed.

1. The metal crusher is mainly composed of a feed inlet, a fixed cutter head, a fixed cutter head, a chassis, a grate, a reinforcement device, a rotating shaft, a reducer, a motor, and a discharge port.

2. The liner and hammer head of the crusher are processed by heat treatment, with good hardness and strong toughness.

3. The metal crusher uses the crushing principles of high-pressure shearing, heavy impact, and shredding. It only needs to simply change the shape of the cutter head to achieve the effects of crushing, separation, rust removal, impurity removal, and compaction in one machine. The finished product can be ever-changing from shape to size.

4. Through the unique metal pressing material, the metal crusher can compress the material and then crush it to improve production efficiency.

5. With the low speed, it realizes the characteristics of no splash, no pollution, no noise, no dust, more energy saving, safer, etc., which is suitable for crushing and processing of more materials.

| Model | Power | Dimension | Capacity | Weight |

| DW-600 | 22KW | 1400*1000*2500mm | 500kg/h | 1t |

| DW-800 | 37KW | 1800*1200*2900mm | 1000kg/h | 1.6t |

| DW-1000 | 55KW | 2300*1600*3200mm | 2000kg/h | 2.5t |

If you need our products please write down any questions, we will reply as soon as possible.

Please enter the product you are searching for