1t/h wood charcoal rods line

wood crusher DW40

dryer DW325

sawdust briquettes machine DW50

carbonization furnace Φ1.5m

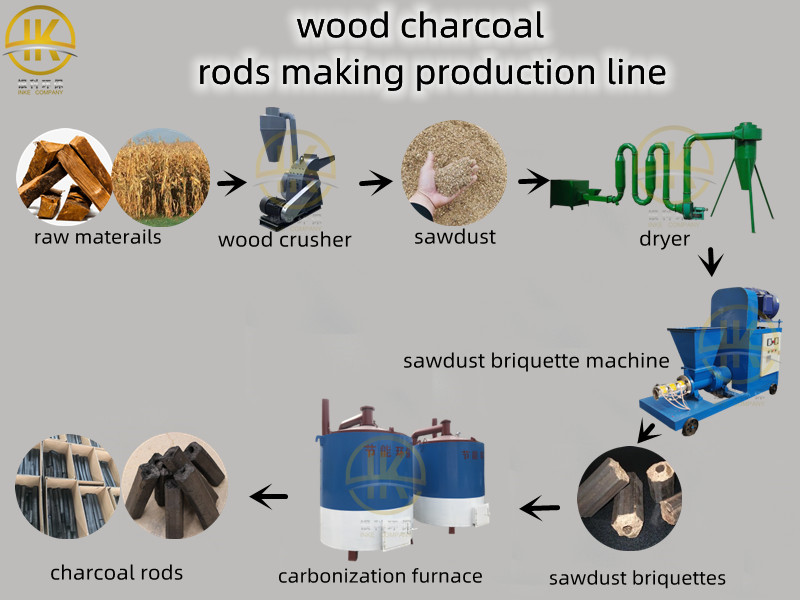

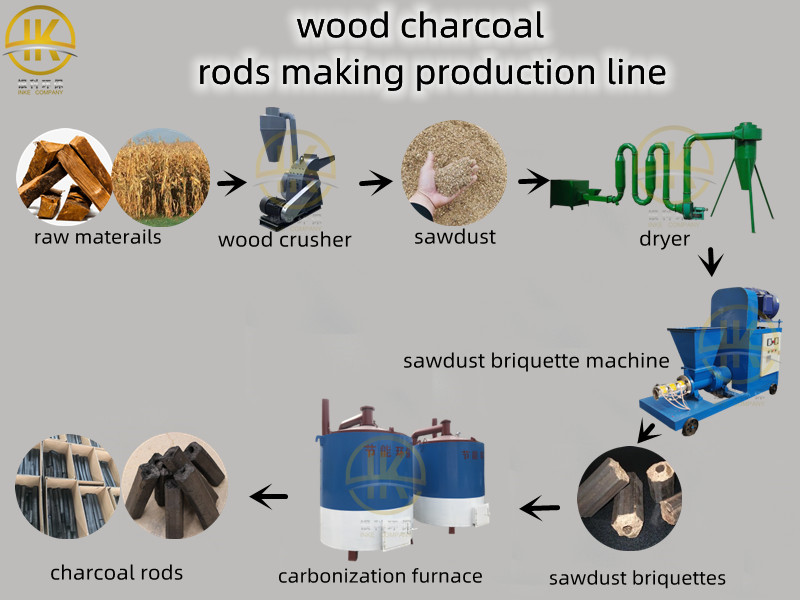

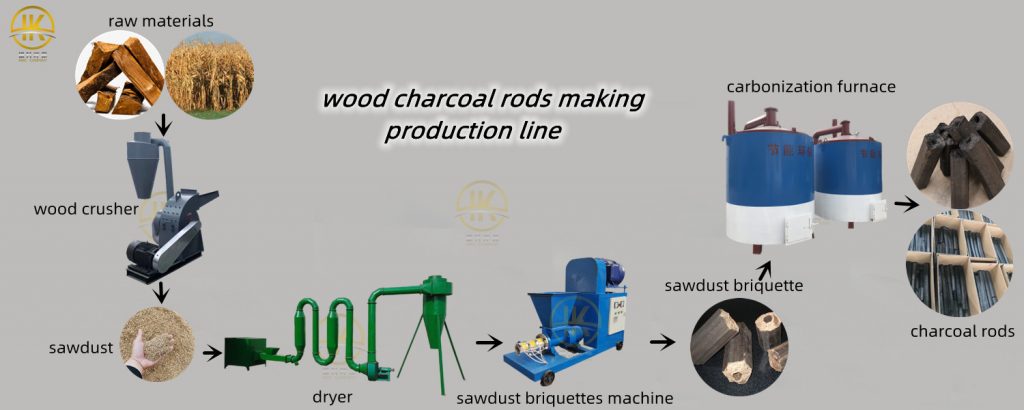

The wood charcoal rods making production line, raw materails can be lots of things, wood logs, woo chips, agricultural wastes, like cutton stalks, rice husks, peanut shells, corn cob,wheat stalks ect.all of them coming from the wastes, we can recycle them into wood briquette and charcoal rods for heating and cooking , environmental protection.

how we run them into heating sources

how we run them into heating sources

step 1: turning the wood logs and wood particles into sawdust shape, for the powder shapes things no need this, like rice husks,peanut shells, they can be pressed into briuqettes directly.

step2: drying program, the raw materials has a certain amount of moisture itself, so we need to dry them first before putting them into sawdust briquettes machine, the mositure should be less than 10%.

step3: forming briquettes program, feeding the dry sawdust into the sawdust briquettes machine for making regular shape of rods,normally we have hexagon shape and cubic shape with holes in the middle.

step4: carbonizating, here we comes to the final steps of making charcoal, put all the wood briquettes into the carbonization stove one by one, after 8 hours working , you will get charcoal rods then.

our wood charcoal rods making line in algeria, you can see the line in the pictures, there is wood crusher and dryer.

the advantages of the charcoal line

1, easy to operate the whole line

2, if your raw materails moisture is dry enough, you can cut off the dryer in the line.

3, you can expand you line capacity by adding more sawdust briquettes machine sets, and carbonization furnace.

If you need our products please write down any questions, we will reply as soon as possible.

Please enter the product you are searching for