bbq charcoal making machine

DW180

Motor:22kw

Capacity :1000kg/h

Weight :1200kg

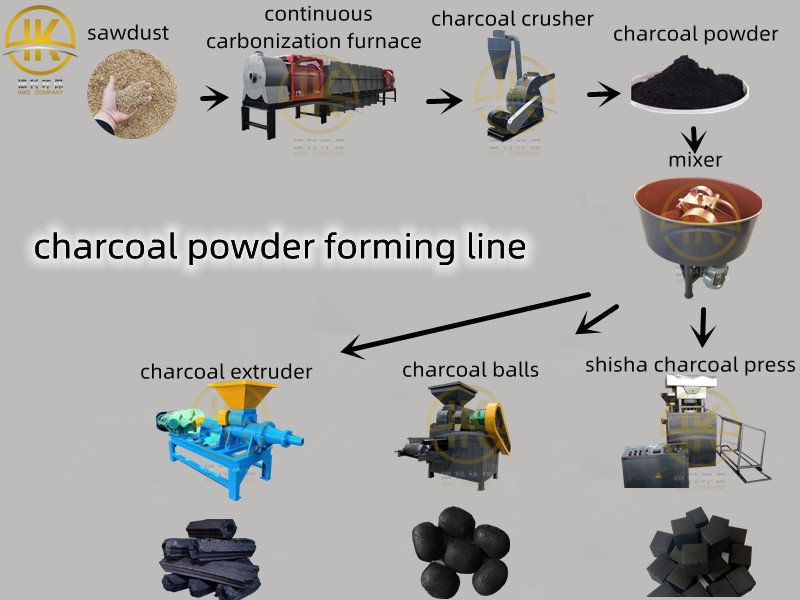

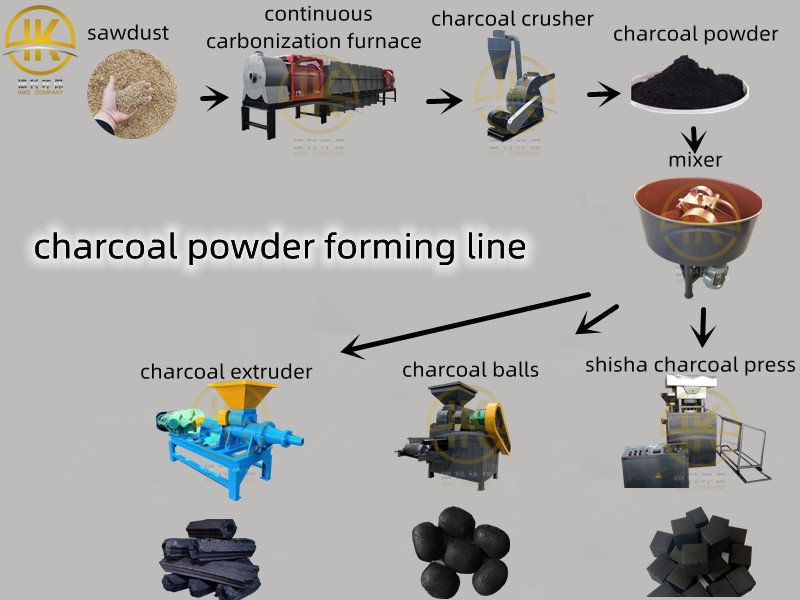

the working pinciple of wood logs charcoal making machine

The working principle of the wood logs charcoal making machine ,The rotating impeller inserts the original carbon powder from the feeding port, and pushes the carbon powder forward. The original carbon powder is gradually compressed, and the particles are close together, and at the same time, relatively large agitation and mixing are generated.

At this time, there is strong friction and shear between the original toner particles, between the particles and the blades, and at the same time, under the action of heat generation, the temperature of the original toner powder rises, the moisture and the binder are more uniform, and the plasticity of the toner powder is improved. Also greatly increased, and then through the control of the mold cone, the carbon powder particles are compressed more tightly, and then pressed into the straight part of the mold, and the coal rod machine is formed.

for the wood logs charcoal making machine, the shapes are various, it can be changed by changing the moulds,like hexagon shapes, cubic shapes, fingers shapes etc.and the batch of bbq charcoal making machines of 3sets are underprocessing in the warehouse.

the raw materials could be apple wood, bamboo,coconut shell,palm kernel shells and straws…

click this video to see how it works

click this video to see how it works

for the bbq charcoal making machine, the shapes are various, it can be changed by changing the moulds,like hexagon shapes, cubic shapes, fingers shapes etc.and the batch of bbq charcoal making machines of 3sets are underprocessing in the warehouse

| Product Name | Model | Capacity | Dimension | Main Power |

| Charcoal

extruder Machine |

DW160 | 500kg/h | 1950*1260*1080MM | 11KW |

| DW180 | 1000kg/h | 2000*1360*1200MM | 18KW |

If you need our products please write down any questions, we will reply as soon as possible.

Please enter the product you are searching for