rice husk charcoal rods making machine

DW180

Motor:22kw

Capacity :1000kg/h

Weight :1200kg

rice husks charcoal rods making machine means that you use the raw materials rice husks, as we all know, there are so many people are using the indigenous method to make charcoal,rice husks is one of them, the indigenous method is good to make charcoal, but that will loose too much charcoal from it, and also, it take long time to get done.

inke machinery can supply the environmental type of carbonization furnace to help you get biochar quickly and with high quality, you can get more enough biochar and save time to be efficient.

Many types of biomass can be used to make biochar.if you are going to make barbesue charcoal, the requirements for raw materials are stricter. according to the characteristics of various materials, the biomass suitable for barbecue charcoal has the below types:

wood: various fruit trees, like apple wood, lychee wood, pear wood etc.

bamboo: various types of bamboo can be made into charcoal

Nut shells: coconut shells,palm shells, coffee shells,and also middle east dates etc.

other types of Biomass: rice husks,corncobs, cornstalks,bean stalks ,wheat stalks etc.

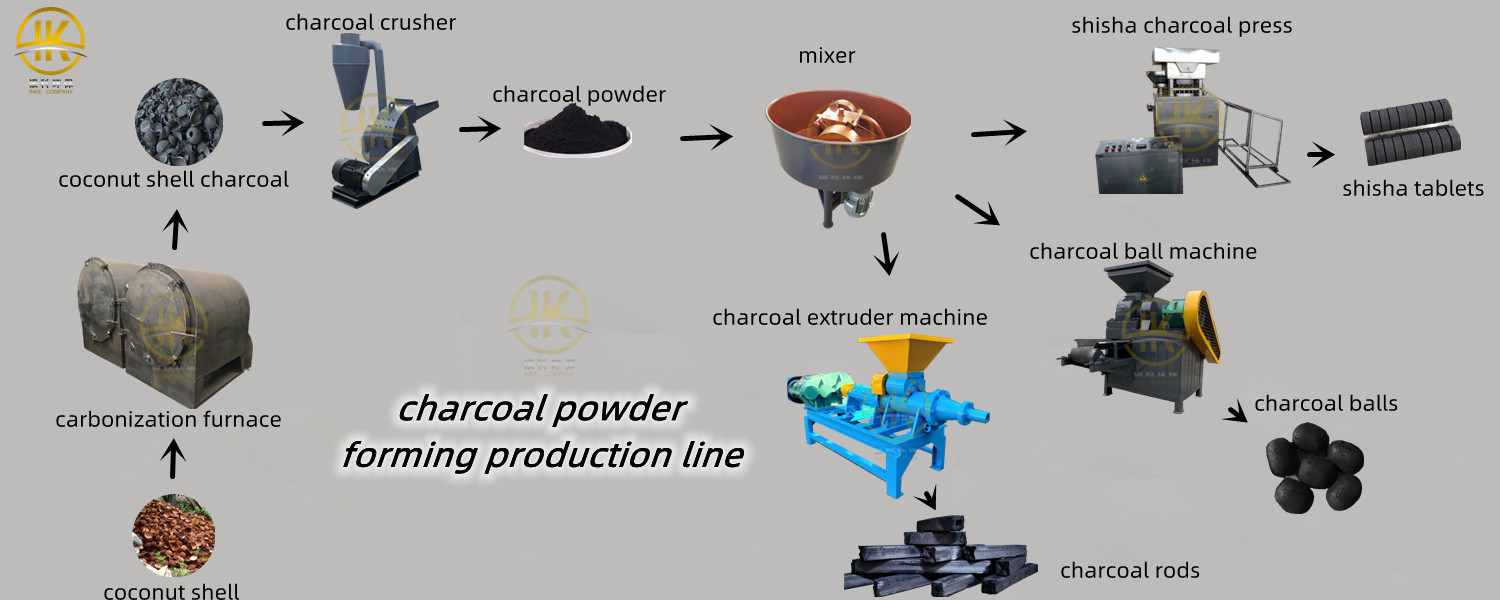

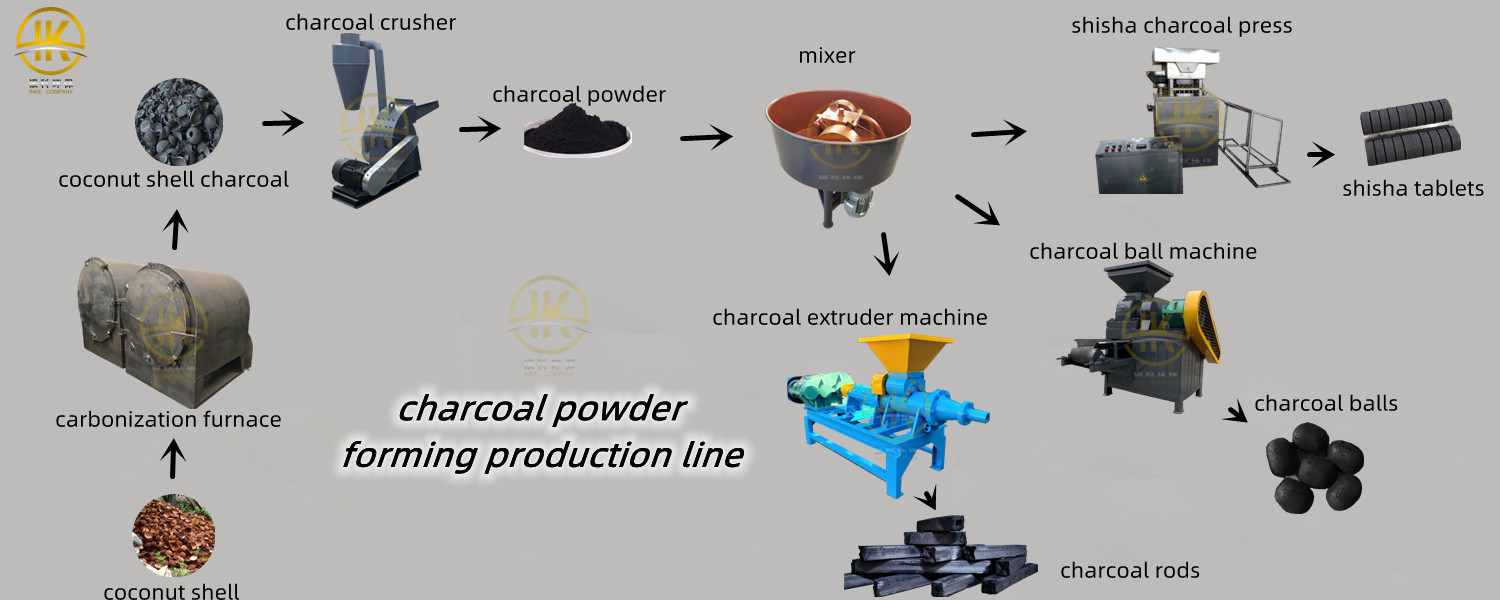

after you get biochar, then you can form them into any shape you want, cause people are used different shape for domestic cooking, like balls shape, pillow shape, cyclinder shape, hexagon shape with hole in middle.the charcoal rods making machine can make so many shapes by replacing the moulds.

you can see the final biochar shape, from the feedback they use the hexagon shape more than the balls shape, cause there a hole in the middle.all these shapes can be used as cooking .

Customers can have an understanding of the cooking charcoal briquettes production process through the following description.

First, determine the moisture, fluidity and size of the raw material. Make sure the raw materials meet the incoming requirements. At the same time, specify the shape of the grilling carbon. If there are special needs, we will provide molding lines to you.

Second, raw materials are conveyed to the main furnace. After heating the main furnace, the temperature rises to 150 degrees, and the substances start to produce chemical and physical reactions in the fully enclosed space. After 15-20 minutes of carbonization, customers can get barbecue charcoal briquettes.

Thirdly, after the combustible gas in the main furnace is purified by cyclone dust removal and water seal, the combustible gas can be used as fuel to heat the main furnace.

Fourth, the excess combustible gas will be burned in the exhaust combustion chamber. After being treated by de-dusting tower and spray tower, it will be discharged up to standard.

, if the customer has special requirements on the shape of the final cooking charcoal briquettes, inke machine forming line can be applied. It can process barbecue charcoal into various shapes and sizes required by customers.

| Product Name | Model | Capacity | Dimension | Main Power |

| Charcoal

extruder Machine |

DW160 | 500kg/h | 1950*1260*1080MM | 11KW |

| DW180 | 1000kg/h | 2000*1360*1200MM | 18KW |

If you need our products please write down any questions, we will reply as soon as possible.

Please enter the product you are searching for